CAVITY WALL INSULATION IN HALIFAX

CAVITY WALL INSULATION BEAD

Frequently Asked Questions

Request Callback

What is a cavity wall?

The external wall of a house is constructed of two brick or block walls, with a gap of at least 50mm between them and they are joined by metal ties.

How is blown bead cavity wall insulation installed?

A series of holes are drilled in the wall, to an approved pattern, through the mortar joints. A specially designed injection gun is used to pressure- blow the insulating bead into the gap between the two walls.

Every millimetre of the cavity is completely filled with the EPS bead. As they pass through the injection gun, the beads are coated with a slow drying bonding agent that glues them together over the next 24 hours.

When the installation is complete the holes are made good with colour matched mortar and any dust from the drilling will be cleaned away.

You will hardly be able to tell that any work has been undertaken – except your home will feel warm and snug!

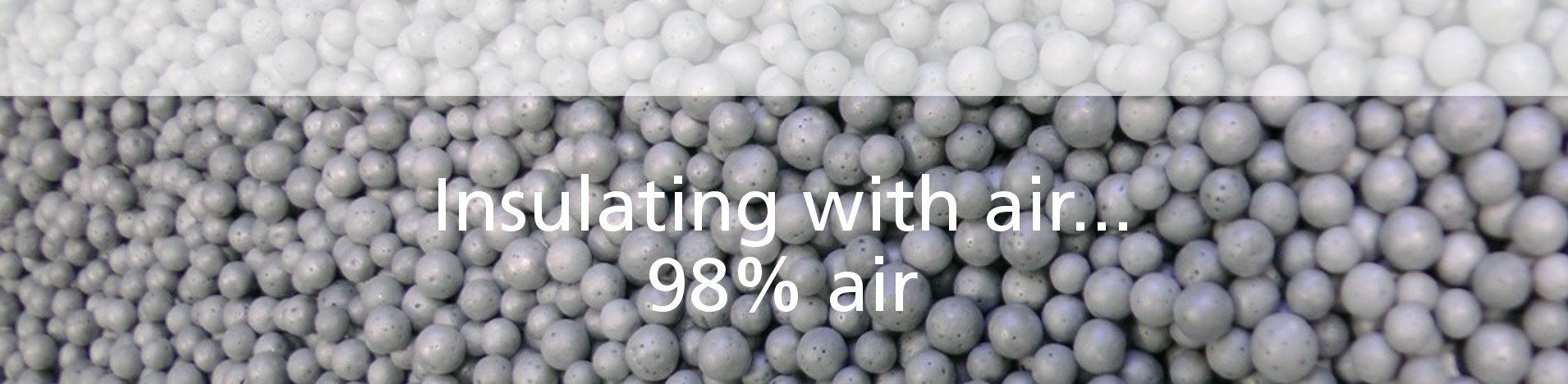

What is EPS bead?

EPS (expanded polystyrene) is a polymer that has been used in the packaging and construction sectors for the past 40 years. You will recognise it as the white polystyrene packaging material that protects high value purchases or you may have a bean bag filled with it. Improved grey beds have been developed with improved insulation performance.

EPS is 98% air making it one of the best naturally insulating materials available. It is completely inert and unaffected by moisture, which makes it an ideal material to insulate homes.

Why are the beads bonded together?

The bonding agent creates a stable, continuous layer within the cavity preventing any movement or sagging of the insulation over time and also any loss of bead if the walls are drilled at a later date.

How long does it take?

Blown bead cavity wall insulation usually takes around two hours, depending on the size of the property and how easy it is to access.

How do I know if my house is suitable?

A qualified surveyor will come to assess your property and to advise you on the grant available. If you send your contact details to us we will arrange for a surveyor to visit you.

Do I have to prepare my property for the installation?

The Technician who performs the installation will need access to all walls, including those with garages or conservatories attached to them. If you have any walls on a boundary, you should ask for your neighbours' permission for the Technician to go on their property if necessary.

The drilling creates some vibration, it would be sensible to remove ornaments on the external walls.

It will help the Technician, if there are no vehicles or objects close the walls that he needs to access.

Does the Technician need to come inside?

Yes, he will need to make checks before and after installation, including any heating appliances.

What about a semi-detached property, do the blown beads go into the next house?

If the other house is not already insulated, the Technician will fit a cavity barrier at the party wall line.

How can I be sure the Technician is competent?

All Technicians in charge of an installation have been trained by the system designer and the installing firm to ensure they are fully competent in cavity wall insulation.

They will carry a training card, please ask to see it.

Will ventilators in the external walls be a problem?

Ventilators that supply combustion air to fuel burning appliances or those at ground level that ventilate below timber floors will be kept safe.

The Technician will investigate these ventilators to check they are already sleeved. If they are not, the Technician will remove them and seal around them to ensure they are not blocked by the insulation.

Redundant vents, such as cavity vents or vents that used to supply air to open fires in bedrooms maybe closed off and redundant air bricks can be filled. The Technician will discuss each of these with you.

is blown bead cavity wall insulation covered by a Guarantee?

Blown bead insulation will be covered by a 25 year guarantee, from the list of ofgem approved companies.

Will my house feel warmer?

The unique properties of EPS bead ensure that heat loss is greatly reduced and its location within the cavity will introduce the added and lasting benefits of thermal mass into your house. The house will feel warmer and maintain a more even temperature throughout the whole day.

Can existing insulation be removed?

Existing blown cavity wall insulation can be removed and replaced with superior performing EPS bead.

How long will the insulation last?

For the life of the building, as stated on both the KIWA agrement the British Board of Agrement certificates.

If I have concerns after the installation, what should I do?

FREE, No Obligation Survey

Initially you should notify the installation company who are responsible for the installation of the blown bead system.